While the federal government continues to spin its wheels on cannabis legalization, the industry remains fragmented, with individual states doing what they can to create consistent and safe medical and recreational marketplaces.

Despite the uncertainty in the legalization landscape, many in the cannabis industry are forging ahead with standards that could eventually be applied nationwide. ASTM International is a multi-industry organization whose members have developed more than 12,000 standards. Darcie Moran, quality assurance manager at Vantage Hemp in Greeley, Colorado, is one of those members and she’s recently been working on two new standards for the cannabis industry.

The first is focused on change control, which requires any critical manufacturing change to be documented and captured within the quality management system. Moran’s proposed standard would add a temporary change portion.

“We saw a lot of supply chain issues where suppliers were not able to supply critical materials and a lot of manufacturers needed to switch vendors. This would give people the flexibility to make temporary changes or implement temporary solutions to keep production and operations moving,” she said.

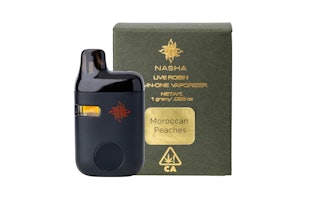

The second standard is looking at segregating cannabinoids in the manufacturing space and implementing distinction within receiving and production systems between different cannabinoids. It would also involve conducting an assessment of facilities to better bring more awareness around cannabinoids using color-coding systems and or other means of avoiding mistakes.

“I feel it’s pretty critical for our industry to be able to do this and provide guidance for producers, which will help bring about awareness and help people comply and avoid mixups,” she said.

Cannabis Equipment News recently spoke with Moran about her work developing standards within Committee D37 at ASTM and what long- and short-term impacts those standards could have on the cannabis industry.

CEN: It seems like cannabinoid mixups have the potential to really chip away at the credibility of the cannabis industry.

Darcie Moran: Exactly, and cannabis is really unique because you can’t tell just by looking at it that there’s THC. There really is no genetic difference between a hemp plant and a cannabis plant. It’s the same genus species. It really comes down to analytical test reports. I think that’s why it’s really critical to have some other way to distinguish what that product is, whether that's a visual queue or a barcode with a COA (certificate of analysis).

CEN: Could something like this help to streamline the cannabis manufacturing process?

Moran: Definitely, I think both of my standards would help. It’s interesting, being in extraction, when you go through the initial stages of extraction, you don’t necessarily selectively extract. In my world it’s CBD but in the cannabis world it’s THC. So, I think it would help because as you go through your different refinement stages or mixing stages, having that confidence and clear sense of direction for the products that you’re making will only make things easier and more efficient during production.

CEN: Has Committee D37 developed other standards for the cannabis industry?

Moran: Yeah, they’re looking at how to determine intoxicating cannabinoids and creating a standard to classify the level of intoxication. It involves using the consumer experience with THC to measure the intoxication.

CEN: Is that something that would be used in packaging?

Moran: No, it would more be used for risk assessment on the governing end of things. In regards to packaging, [the Committee] also has a section on sustainability and environmental, and overall quality management systems look at labeling as well.

CEN: What are the short- and long-term benefits of adopting international standards for the cannabis industry?

Moran: Right now, we’re kind of in a debacle in regards to classifying cannabis products. Depending on where you are it can be seen as a drug, a food, a dietary supplement or just flat-out illegal. I think adopting international standards would allow for people to sell products that are safe; safe to produce and safe to ingest.

Overall, I think if we could come to a more universal standard it would allow for international distribution and I think a lot more collaboration and progression in the industry.

CEN: How much of the work that ASTM is doing in the cannabis industry could potentially inform legalization at the federal level?

Moran: So, ASTM will not lobby any kind of agenda. But any kind of regulating agency could approach ASTM or ASTM could approach a regulating agency and present the standards that we’ve compiled for cannabis, which then gives the government agency an out-of-the-box regulation around cannabis that’s created by industry experts. And that’s kind of what ASTM is known for, creating standards and then seeing those standards being adopted by some regulating agency. I don’t think it’s too far-fetched to see ASTM selling their standards for cannabis to these governing bodies that are trying to introduce CBD and THC into their countries but don’t really have the know-how regarding what needs to be done to keep it a safe and quality product.

CEN: So, it’s not your primary goal but the groundwork that ASTM is doing can function as a resource for governing bodies.

Moran: Exactly, and our standards could be adopted into law. That would be a huge goal for D37, to have those standards utilized in practice and for people to be using these as guidance in their manufacturing.