In the cannabis world, producing pre-rolls used to be a serious headache, especially for smaller operators. Not even speaking of hand-rolling, machine production of pre-rolls was time-consuming, labor-intensive, and often felt like it was designed for the big guys with deep pockets. And speaking honestly, those pre-rolls weren't even any good.

But things are changing. Automation is no longer just a tool for the mega-producers and MSOs; it's leveling the playing field and giving smaller cannabis companies a shot at making a real impact in the pre-roll market.

Affordable Automation: Leveling the Playing Field

For a long time, automation sounded like a buzzword for "expensive," something only large-scale businesses could afford to dabble in. Equipment was constantly ported over from other industries and retrofitted haphazardly in attempts to handle the quirks of flower. But things have shifted. The latest pre-roll machines aren't these massive, confusing monsters that require a team of engineers to operate. Because they're being designed for cannabis, they're now more compact, user-friendly, and surprisingly affordable than ever. This means smaller cannabis businesses can finally automate their production without needing a major cash infusion.

By adopting these new automation solutions, small businesses can achieve a level of craft and consistency that used to be out of reach. We're talking less waste, more efficiency, and a product lineup that can stand toe-to-toe with the big brands. And in an industry where every dollar counts, cutting labor costs and upping your production game can be a total game-changer.

Quality Control

One of the biggest perks of automation isn't just cranking out joints faster, it's making sure every single one of them is top-notch. Some of the best pre-roll machines come with built-in software that handles quality control like a champ. Think of it as having a quality assurance team in a box, ensuring each joint has the right weight, density, etc.

For smaller businesses, this kind of quality control was almost impossible without a team of experts. Automation brings that expert-level consistency into the realm of possibility for the little guys. And because some machines can collect data on each batch, businesses can make tweaks on the fly, keeping their product quality high and their customers happy.

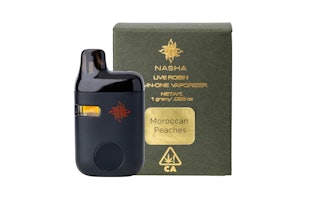

The RollPros Blackbird.RollPros

The RollPros Blackbird.RollPros

Market Entry Strategies

Now that the barrier to entry has dropped, smaller cannabis companies can finally compete in the pre-roll market without getting steamrolled by larger operators. But having the right equipment is only part of the equation—you've got to use it well.

The right automation lets small businesses be nimble. They can quickly adapt to market trends, experiment with different strains and infusions, and tailor their products to exactly what their customers actually want. Small brands can carve out their own niche, whether that's budget-friendly joints, eco-conscious options, or those with unique flavor profiles and limited drops. And we have proof of this success. Some of our clients with zero experience have seen award-winning success in just under a year of operation.

The beauty of these newer automated pre-roll machines is their scalability. Start small, see what works, and grow from there. Just take a look at customization options coming out on new machines. I believe any business should have the ability to ease into the market without risking everything on a single rollout.

The RollPros Blackbird.RollPros

The RollPros Blackbird.RollPros

A More Inclusive Pre-Roll Market

Automation has brought us to a tipping point in the cannabis industry. It's an equalizer that lets smaller businesses step into the ring with confidence. With accessible automation tools, small operators can offer high-quality pre-rolls that meet market demand.

In a space where the biggest brands often dominate, the rise of automation is making room for more diverse offerings. This is also great news for consumers like myself, who get more, better, choices. For small businesses, they finally have the tools they need to shine.

Automation is reshaping the cannabis industry by breaking down barriers for small businesses, especially in the pre-roll market. With affordable, easy-to-use automated machines and quality control software, smaller operators can produce consistent, high-quality products. This makes it easier than ever for brands to carve out their space in the market and thrive alongside the industry giants.

Kyle Loucks is the founder and CEO of RollPros, an automation company disrupting the cannabis industry using its groundbreaking TruRoll technology that mimics the precision of hand-rolled quality joints at scale.

Prior to RollPros, Loucks held various lead engineering and technical roles for companies ranging from innovative medical device startups to tech giants like Hewlett-Packard and Georgia Pacific. He also played a key role in developing optics hardware for Facebook's Oculus VR system.

With conventional pre-roll joint production processes notorious for churning out inconsistent and sub-standard quality joints, Loucks saw an opportunity for innovation and automation. Since 2020, Loucks and the team at RollPros have helped cannabis companies succeed by arming them with the industry-leading technology they need to create premium-quality pre-rolls that build consumer loyalty while reducing overhead, boosting efficiencies, and eliminating tedious manual labor processes.

Loucks holds a Bachelor of Science in Mechanical Engineering from Washington State University in Pullman, WA.