Companies have been looking to automation to gain a competitive edge and address the challenges faced by scaling up operations. With the arrival of the COVID-19 crisis, suddenly the additional benefits afforded by automating have become even more clear. Businesses are thinking about how to increase their efficiency and profits while also focusing on operating a facility safely and ensuring a comfortable and safe working environment.

By automating your post-harvesting processes, you can see rapid gains in efficiency and production while maintaining high quality standards, and saving substantial employee hours. These are benefits in any climate, but especially beneficial during the COVID-19 crisis.

Being able to scale at the right time for your business and not skip a beat when it comes to expansion is not just desirable; it's essential for many companies' survival. Businesses can't just put their pre-Covid expansion plans on hold if they have already funded a portion of their growth plan. Competition is getting stiffer, and investment capital is more challenging to secure under the current circumstances. Automating can provide a leg up for these businesses and give them an opportunity to up their production capabilities instantly.

Standardizing product control leads to higher quality, consistency, and the ability to get top dollar at the point-of-sale. Retaining consumer loyalty is also a significant consideration for businesses. Consistent quality leads directly to customer loyalty in this competitive market. The modern consumer is demanding and very aware of the wide range of options available. Your product has to be the same every time, or the consumer loses interest.

The availability of real-time data is also a considerable advantage. Tracking exact weights and gathering strain-specific data along the automation chain helps businesses make the best decisions from an operational standpoint. Employing mechanized sorting can help identify if the material is too small to go into a top-shelf flower product. For example, it can be redirected to extraction, which ensures that the high-value material goes to the highest-value production stream, avoids waste, and ensures consistency.

Employing a smaller, highly-trained staff in the long term is a substantial cost savings. It can be time-consuming and expensive to train seasonal employees. Automation minimizes, or in some cases, eliminates this problem. The risk of product contamination is also significantly reduced. The fewer people you have handling the product, the less chance of contamination. The industry is fraught with price volatility, regulation changes, and increasing competition. Automation lets you control how you handle your product and quality.

Automating a portion of your production line or the entire process makes it easier to set up a socially-distanced facility. With the option to have conveyors move product from one station to another, you no longer need employees in close proximity working side by side. It ultimately creates a safer working environment for employees and lets staff know that you value their health and safety.

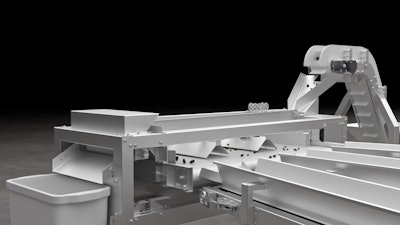

So, you've decided to automate. How do you determine what part of the process to automate first? Identifying your bottlenecks is the first step in making that decision. Sorting and trimming are often the two areas that provide the most gains and the ones that most businesses will benefit from automating first. Mechanized sorting is not just easier, but it can help preserve the terpenes in your raw material because the faster you sort, the less time your material is exposed to a less controlled environment in terms of temperature and humidity. Automation helps retain the integrity of the terpenes and keeps you from losing value during processing.

A key consideration should be processing the most material while losing the least amount of value. You want to look for a machine that can sort at least 1.5 pounds per minute and does not use vibration to move product, but instead uses a conveyor system which is gentler and encourages terpene integrity.

The GreenBroz Sorter Conveyor.

The GreenBroz Sorter Conveyor.

When selecting a trimming machine, it is essential to look for a machine where all plant-touching surfaces are surgical stainless steel. Cleanability is also a big concern. All parts need to be washdown compatible and quick and easy to disassemble and re-assemble. Time spent cleaning is time not spent processing. You also want to look for a machine that uses a more gentle rolling motion to protect the delicate trichomes, rather than the more harsh end-over-end tumbling devices. Look at your ROI. If you can reduce your cost even 10% per pound processed, that's a huge savings, especially at scale.

Larger businesses will likely need to automate all trimming. In contrast, the small or medium operations will, in some cases, machine trim first and then hand-finish, especially if their focus is top-shelf craft flower.

The type of motor used in a machine is not often considered, but it should be. Choosing a machine with a quiet motor can enhance safety at your facility. If employees can hear each other easily, this allows quick and effective communication should a safety concern arise. Many operators have commented that noise attenuation makes a big difference in the ease of day-to-day operations.

Depending on your end products, you should look at automating after sorting and trimming. Some producers focus on the currently trendy frosted nugs or cones with kief, in which case you would look to automating extraction. If your focus is on pre-rolls, you would add an automated rolling machine.

The future of automation will be heavily systems focused. Machines will be grouped in assemblages that handle the main bottlenecks and processes that can be made more efficient for each business. The larger players will be looking for full end-to-end systems to automate every step of the process from beginning to end. The raw material will go in one end, and packaged, shelf-ready consumer products will come out the other. We will also see a fair amount of customization of large scale systems as they become more sophisticated. Operators will be able to have systems tailored to their needs. Cannabis is still a very new industry rife with exciting developments.

In the future, large scale cannabis operations will look more like the big operators in traditional agriculture. The COVID-19 crisis may have accelerated automation in the cannabis industry, but the long term benefits are the reason it is here to stay.