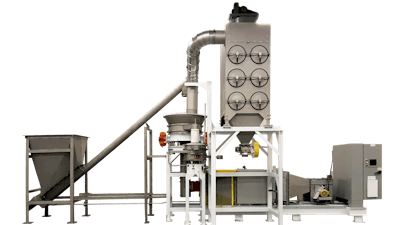

CHICAGO -- Kason Corporation and ABM Equipment have introduced a patent-pending 2-stage fluid bed dryer that can dry up to 10,000 pounds of cannabis per hour with minimal cannabinoid loss. Ideal for batch or continuous drying of cannabis biomass, the VIBRO-BED fluid bed dryer uses heat as an accelerant rather than a primary driver for evaporation, burning off less CBD than alternate technologies.

Fluid bed dryers are an improvement over belt and tumbler dryers, since the fluid bed pushes air up through the product while it is being constantly shifted with vibration. This fluidizes and maximizes exposure to air, speeding the drying process while maintaining product integrity. Because the product is suspended over the airstreams, this method increases the surface area of the product being exposed to dry air for greater efficiency and drying consistency. Cannabis processors are also able to use the Kason VIBRO-BED fluid bed dryer to capture and return lost trichomes to each batch.

Belt dryers, in contrast, only pull air from above via vacuum, which creates concentrated or localized air streams that require higher temperatures and/or more time to remove inevitable wet spots that occur throughout the biomass.

Billy Toseff, founder of Columbia Hemp Trading Company, said the new systems have resulted in a dramatic increase in both quality and productivity at his facilities.

"ABM has reliably and consistently elevated our ability to maximize performance and subsequent yields from plants to refined goods,” said Tosheff. “In fact, we hope to keep them busy enough so that none of our competitors can get them on the schedule!”

Kason and ABM Equipment have also adopted a 2-stage drying approach to further improve efficiency. Single-stage units have the advantage of fitting in tighter spaces and budgets because they involve a single dryer, but dry more slowly because the maximum temperatures allowed must be suitable for outgoing, dry product.

The 2-Stage approach is able to use hotter air for the wet cannabis in the first stage. Then, the separator removes stalks and stems before sending the semi-dry product on to the cooler, second dryer. By using hotter air on wet product and avoiding the drying of unwanted material, 2-stage approaches are able to achieve 4-12% moisture in less time with less energy consumption.

“The 2-stage approach is a tremendous advancement compared to larger and more expensive tumbler and belt dryer systems,” explained ABM Equipment Owner Jeff Walling. ABM is representing Kason in the market as its exclusive system integrator for cannabis. “This method provides us with far more precise temperature control throughout the process, which leads to greater cost-efficiency and yields the premium biomass material the industry requires today.”

“Kason’s cannabis drying solutions are designed to offer consistently high performance with minimal maintenance and downtime,” said Henry Alamzad, senior vice president of Advanced Materials Processing, the parent organization for Kason Corporation. “The fluid bed drying approach is not only capable of processing more biomass in less time but is also more energy efficient and compact than other drying methods.”

Kason’s innovative, circular designs ensure easy and thorough cleaning. The VIBRO-BED dryers are available in sturdy, high-performance, and food-grade stainless steel that is fully compliant with USDA, FDA and other international standards.

To learn more, visit www.abmequipment.com or www.kason.com.