Carbon dioxide (CO2) is pivotal in photosynthesis, driving plant energy production. In indoor medical cannabis cultivation, maintaining optimal CO2 levels is imperative for healthy growth.

Modern IoT devices have ushered in a new era, enabling precise monitoring of CO2, and bridging the gap between traditional horticulture and innovative cultivation practices.

Why Monitor Carbon Dioxide?

- The Importance of Carbon Dioxide in Cannabis Growth: CO2 is a primary substrate in photosynthesis. Adequate levels of CO2 can significantly accelerate the growth rate, leading to higher yields and robust health of the cannabis plant.

- Effects of Improper CO2 Regulation: Insufficient CO2 levels can stunt plant growth, while an excess can cause poor ventilation, leading to potential mold growth and other related issues. An excess of CO2 can also cause dangerous conditions for workers. The gas is odorless, colorless, and tasteless, so employees can be negatively affected by entering a grow saturated with CO2.

What Are We Monitoring?

- CO2 Concentration: Represents the amount of carbon dioxide present in the air.

- Example Value: 1200 ppm (parts-per-million).

- How This Telemetry is Represented: CO2 concentration is typically visualized using time-series graphs on IoT dashboards, reflecting its variations over time.

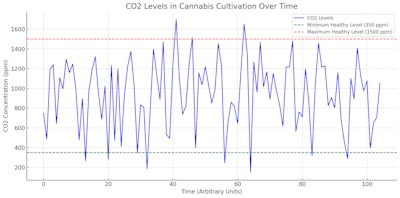

The above graph showcases the fluctuations in CO2 levels over a certain period. The green and red dashed lines demarcate the healthy range for CO2 (350-1500 ppm). As evident, while the CO2 levels mostly hover within the healthy range, there are sporadic dips and spikes, underscoring the need for continuous monitoring.Shawn Deggans

The above graph showcases the fluctuations in CO2 levels over a certain period. The green and red dashed lines demarcate the healthy range for CO2 (350-1500 ppm). As evident, while the CO2 levels mostly hover within the healthy range, there are sporadic dips and spikes, underscoring the need for continuous monitoring.Shawn Deggans

Devices for Monitoring Carbon Dioxide

- CO2 Monitors and Controllers: These devices provide real-time CO2 level readings and can be set to automatically adjust CO2 levels, ensuring they remain within the desired range.

- Infrared Gas Analyzers (IRGA): Leveraging infrared technology, these devices offer highly accurate CO2 measurements, which is especially beneficial in larger cultivation setups.

- Tuned Diode Laser (TDL) Analyzers: These high-end devices use laser technology for precise CO2 measurements, suitable for research and large-scale commercial grow.

Interpreting Data

- Understanding the Ideal Range: For cannabis cultivation, maintaining CO2 levels between 1000-1500 ppm is generally considered optimal.

- Recognizing Outliers: Sudden drops or spikes in CO2 concentration can indicate ventilation issues, equipment malfunctions, or other environmental factors.

Testing and Calibration

- The Importance of Accuracy: Precise CO2 readings are paramount, given the sensitivity of cannabis to its environment.

- Testing Procedures: Regularly cross-check readings with reference CO2 monitors to ensure accuracy.

- Calibration Steps: Most CO2 monitors require periodic calibration using a known gas concentration, typically done using calibration gas canisters.

Using Data for Cultivation Decisions

- Adjusting Ventilation and CO2 Supplementation: Depending on real-time data, growers can adjust ventilation systems or CO2 supplementation devices to maintain optimal levels.

- Incorporating Other Data: Considering CO2 data in tandem with other parameters like temperature and humidity can offer a holistic understanding of the plant environment.

- Long-term Planning: Continuous CO2 monitoring can guide decisions on equipment upgrades, room design, or overall cultivation strategies.

Monitoring carbon dioxide isn't just a technical aspect of plant care; it's a cornerstone of ensuring optimal growth and health of medical cannabis plants—and in some cases, the health of your employees.

With IoT devices offering unprecedented precision, cultivators are now equipped with actionable insights that can significantly enhance their cultivation success. Embracing this technological revolution is not just an advantage; it's gaining recognition in modern cannabis cultivation.

This article is part four of an exclusive new series that will guide you through the essence of each of the fourteen pillars of plant care, focusing on indoor growth and revealing the nuances of how IoT can be a game-changer for cultivators.

Shawn Deggans owns Green Nanny, an IoT, AI and data consulting company focused on helping growers spend more time in the garden and less time struggling with technology.