Air distribution plays a pivotal role in ensuring the optimal growth of medical cannabis. An even and consistent air flow can impact plant health, growth rate and yield.

With the advent of Internet of Things (IoT) devices, monitoring and managing air distribution has never been more precise, allowing cultivators to achieve optimal indoor environmental conditions seamlessly.

Why Monitor Air Distribution?

Air distribution affects the uniformity of temperature and humidity in the grow space. Proper airflow ensures that every part of the plant receives an even amount of heat and moisture, promoting uniform growth and preventing the development of micro-environments that could be detrimental to the plant.

Uneven air distribution can lead to hot or cold spots (micro-environments), causing uneven growth. It can also foster mold and pest infestations, particularly if stagnant air becomes humid.

What Are We Monitoring?

Telemetry Types:

- Airflow Speed: Measures air velocity, ensuring it's neither too aggressive (which can damage plants) nor too gentle (which may not provide adequate circulation).

- Example Value: 0.5 meters per second.

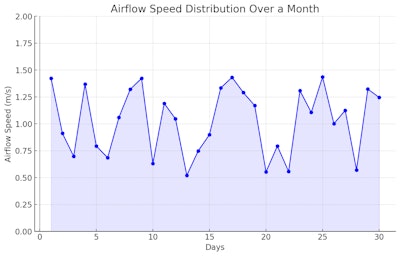

- How This Telemetry is Represented: Data for air distribution is typically displayed in graphs or tables on IoT dashboards, showcasing the airflow's speed and direction over time.

Devices for Monitoring Air Distribution:

- Anemometers: Measure wind speed and are crucial for indoor growers to ensure optimal airflow. However, they only provide point measurements, so several might be needed for a comprehensive view.

- Thermo-hygrometers: While primarily used to measure temperature and humidity, they can provide insights into the effectiveness of air distribution when placed at various points in the grow space.

- CO2 Monitors: CO2 Monitors can indicate air quality but aren't directly related to monitoring air distribution. They are crucial for understanding if plants are getting fresh air but don't provide direct insights into airflow.

Interpreting Data:

- Understanding the Ideal Range: For cannabis cultivation, maintaining an airflow speed between 0.3 to 0.8 meters per second is generally considered optimal.

- Recognizing Outliers: Sudden drops or spikes in airflow speed or inconsistent readings across devices can indicate blockages, equipment malfunctions, or other issues.

Testing and Calibration:

- The Importance of Accuracy: Just as a thermostat's accuracy is crucial for temperature control, ensuring your devices provide precise airflow data is vital for optimal plant growth.

- Testing Procedures: Use reference devices or send your equipment to certified labs to ensure accuracy.

- Calibration Steps: Regularly calibrate anemometers and other devices as per the manufacturer's instructions to ensure consistent accuracy.

Using Data for Cultivation Decisions:

- Adjusting Fan Speeds and Positions: If monitoring indicates uneven air distribution, adjusting the speed or position of circulation fans can help rectify the issue.

- Incorporating Other Data: Consider air distribution data in conjunction with temperature, humidity, and CO2 levels for a holistic understanding of the grow environment.

- Long-term Planning: Over time, data trends can inform decisions on equipment upgrades, room design changes, or cultivation practices.

Monitoring air distribution is a cornerstone of optimal plant care, especially in the context of medical cannabis cultivation. With the precision offered by modern IoT devices, cultivators can now ensure their plants thrive in an environment where the air flows just right, leading to healthier plants and better yields. Embracing technology in this domain is not just an advantage; it's a necessity for modern cultivation success.

This article is part six of an exclusive new series that will guide you through the essence of each of the fourteen pillars of plant care, focusing on indoor growth and revealing the nuances of how IoT can be a game-changer for cultivators.

Shawn Deggans owns Green Nanny, an IoT, AI and data consulting company focused on helping growers spend more time in the garden and less time struggling with technology.