Just two years ago, the global cannabis market was valued at USD $43.72 billion in 2022. Today, the cannabis industry’s revenue is currently valued around US$64.73 billion. This is a substantial jump, sure, but the best is yet to come—by 2030, the market is forecasted to reach USD $444.34 billion, at a CAGR of 34.03%.

This growth is exciting, no question about it. Especially since the U.S. is expected to lead this growth with the highest revenue gains this year of approximately USD $42.98 billion. But labor shortages, product inconsistencies, and pricing fluctuations might be the chink in the cannabis industry’s armor that inhibits this rapid market growth.

The solution is simpler than you’d think: automation. Surprised? Of course you’re not. It’s no secret the benefits automation brings to all types of businesses in growth mode.

But did you know automation provides a stable, predictable cost in an unpredictable world where raw material prices and labor availability fluctuate? This use case ultimately enables cannabis businesses to achieve greater efficiency and predictability.

Labor Uncertainty and Shortages Squashed by Automation

The Vangst 2024 Cannabis Jobs Report states in the past year, there was a gain of 22,952+ cannabis jobs due to the growth of the industry nationwide as more states legalized recreational use of the plant. However, labor shortages are making it difficult for cannabis businesses to fill these roles. The high turnover rate of the cannabis industry, seasonal demands, and the constantly changing cannabis regulations contribute to the labor shortage and create expensive labor costs that new cannabis businesses can’t afford to keep up with.

Automation reduces dependency on manual labor and enables businesses to stay productive regardless of workforce fluctuations. The best part? Automated systems can be leveraged in cultivation, processing, and packaging—the entire supply chain can be streamlined for enhanced efficiency and productivity with minimal downtime and without headache in an unpredictable labor market.

Thank Automation for Consistent Product Quality

Too often, manual labor leads to product inconsistency when it comes to rolling joints, packaging gummies, sealing bags—you name it. Humans are, after all, humans and are apt to make mistakes. The problem is product consistency is a vital factor in building a great brand reputation and fostering trust between the brand and the consumer. These inconsistencies thwart all that.

Yet with automation, brands can ensure production precision and repeatability. For example, automated trimming machines can ensure flower appearance maintains the same, artificial intelligence (AI) based systems can help ensure proper sorting and grading, and automated joint rolling systems can make certain all joints are the same shape and size, without fear of canoeing.

Ultimately, automation ensures that quality control is not left to human error, but is instead governed by reliable, consistent technology.

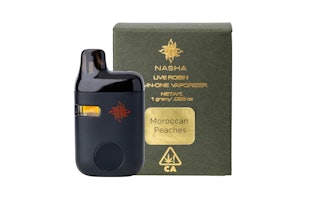

The Stardust is an automated kief-coating robot from Sorting Robotics.Sorting Robotics

The Stardust is an automated kief-coating robot from Sorting Robotics.Sorting Robotics

Automation Eases Inconsistent Pricing and Market Fluctuations

Fluctuating demand, regulatory changes, and supply chain disruptions are just a few of the factors that contribute to the cannabis market’s price volatility. This unpredictable variability makes it challenging for cannabis businesses to remain profitable as it can strain their budgets.

On the other hand, automation is a steady, fixed cost that companies can rely on. It’s no secret that raw materials prices and labor costs vary. But by investing in automation, cannabis businesses create a buffer against dramatic market fluctuations. The result? The ability to ensure better financial planning and a more predictable cost structure.

Final Thoughts

There’s an old expression that says, “change is the only constant.” While that phrase may be true for just about everything in the human experience, one thing is certain: the cannabis market has been historically unpredictable. However, once regulations settle across the world, the cannabis market will eventually be about as stable as corn and tobacco.

In the meantime, automation offers cannabis businesses a better way to stabilize operations, maintain product quality, and manage costs effectively. In short, automation is the key to sustainable and long-term success.

The Stardust is an automated kief-coating robot from Sorting Robotics.Sorting Robotics

The Stardust is an automated kief-coating robot from Sorting Robotics.Sorting Robotics

Nohtal Partansky is the founder and CEO of Sorting Robotics. He is a serial entrepreneur and former NASA-JPL engineer. At NASA-JPL, Nohtal was a cognizant engineer on the MOXIE project; an instrument on the surface of Mars producing oxygen from the Martian atmosphere. After leaving NASA-JPL, Nohtal founded Sorting Robotics with his co-founder, Cassio Dos Santos Jr.

Since the company’s inception, Nohtal has led Sorting Robotics in building innovative equipment for cannabis manufacturers and vertically integrated brands. While building Sorting Robotics, he witnessed firsthand how the lack of automation in the cannabis industry disrupts the value chain and erodes profit margins. Today, Sorting Robotics is working to solve those problems with AI-driven machines deployed across North America.