Our knowledge of cannabis and food digestion has significantly improved over the past 7 years since we launched in 2014. The first white paper we published in 2016, The Art & Science of Cannabis Beverages, identified key concepts that are now considered the gold standard for food and beverage formulations infused with cannabinoids. Nanoemulsions, bioavailability, and fast acting effects are the topic of conversation all over the world. Many companies and products have been built, but you cannot copy quality and originality. The cannabis industry is finally transitioning from pseudoscience to scientific methods thanks to the science of cannabis beverages.

Our second white paper is going to briefly outline how we evolved from pioneering cannabis beverages to crafting cannabis powders. Le Herbe recently reverse engineered resin heads of stalked glandular trichomes located on Cannabis sativa L. We learned about these resin heads from the legendary Marcus “Bubble Man” Richardson. His passion for cannabis educated the masses for decades and offered beautiful macro photography of cannabis trichomes that inspired us to make artisanal products because quality matters. Much love and respect to a true OG.

The resin heads on cannabis trichomes are comprised of secretory cells and a storage cavity with a size ranging from 20- 125µm (micrometer). It considered by most to be a biochemical factory made by Mother Nature. Cannabinoid and terpene metabolites are synthesized in the stalked glandular trichomes on female flowers and include THCA. When heated, the molecule decarboxylates to the bioactive metabolite THC or more specifically delta 9 THC (D9). When humans consume D9 it interacts with receptors in our endocannabinoid system to produce psychoactive and therapeutic effects.

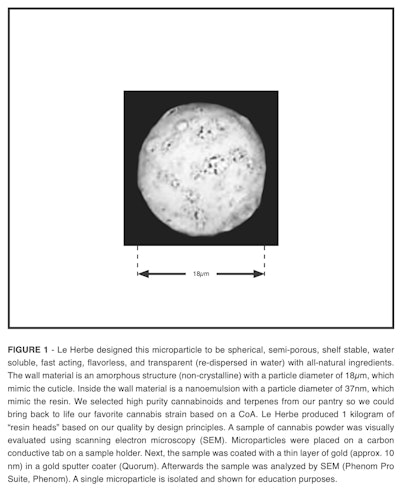

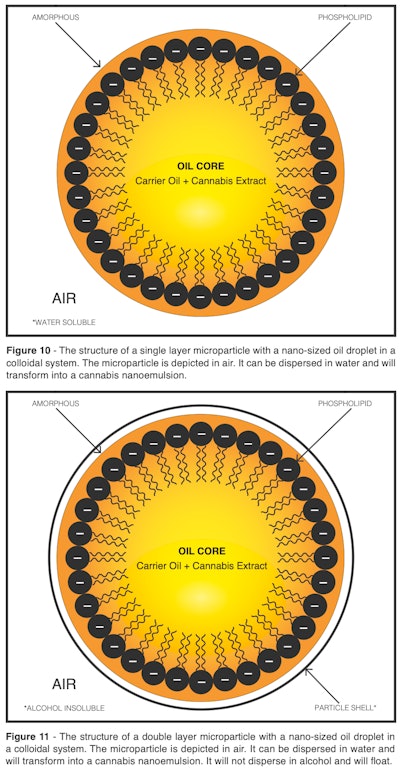

Resin heads made by Le Herbe are called microparticles. Our cannabis powder is a collection of microparticles with a size ranging from 10-30µm. They mimic the resin heads of stalked glandular trichomes. The thin layer of wax present on the cuticle surface of cannabis trichomes can be substituted with commercially available ingredients. One of our primary formulations has a particle shell that protects cannabinoids from oxygen, light, and crystallization just like cannabis. Our resin heads do not contain secretory cells, but they do contain nano-sized oil droplets that mimic resin called nanoemulsions. Liquid particles are measured in nanometers (nm) as opposed to micrometers (µm) for larger particles like powder. The main difference between the cannabis plant and Le Herbe is our resin heads are water soluble. We can make resin heads for inhalation, but we prefer to make cannabis powder for fresh roasted coffee, artisan chocolate, delicious pastries, baked goods, and much more.

We will briefly describe how you can make microparticles from scratch and mimic the resin heads of stalked glandular trichomes. You will learn what types of equipment are needed to make cannabis powder and how quality data is required to be successful. We will update you on how to make a cannabis nanoemulsion and show you how to encapsulate a microparticle. Finally, we will explain simulated digestion so you can design cannabis powder for high bioavailability and stability in vitro. This white paper is not going to provide product formulations, but we will share a standardized method to make cannabis powder and offer guidance.

Particle Engineering

Le Herbe aims to enhance the performance of cannabinoids by formulating them into a defined shape, size, and composition. The science of particle engineering can be divided into two categories, top-down and bottom-up. The former involves the size-reduction of large particles to smaller ones, while the latter generates particles by building them from an atomic or molecular level. We will shrink the particle size in this white paper because mother’s milk showed us how to deliver nutritional and bioactive compounds like cannabinoids.

The following steps can be used to make artisan cannabis powder that is healthy and safe for the consumer. Your product quality is a reflection of the ingredients you use and your understanding of how to make it (Figure 1). Get to know the people who make your ingredients, source the highest quality, and show them some love. Get to know the companies who build your equipment, understand the technology, and show your appreciation. Go to your local coffee roaster, grab a fresh cup, and let’s get started.

Standardized method for making cannabis powder and/or functional ingredients:

1) PARTICLE DESIGN physicochemical, structural, functional 2) EXTRACT SELECTION isolate, distillate, rosin, badder, live resin 3) CARRIER OIL / INGREDIENT SELECTION emulsion, encapsulation 4) ROTOR-STATOR MIXER coarse emulsion (> 150nm) 5) HIGH-SHEAR PROCESSING nanoemulsion (< 100nm) 6) DYNAMIC LIGHT SCATTERING + back (173°), side (90°), front (13°), PDI 7) ZETA POTENTIAL ±30mV (ζ), effects of pH 8) SPRAY DRYING microparticle (µm), evaporation rate, yield (%) 9) LASER DIFFRACTION PSD, SEM 10) SIMULATED DIGESTION bioaccessibility / bioavailability

Le Herbe

Le Herbe

Nanoemulsion

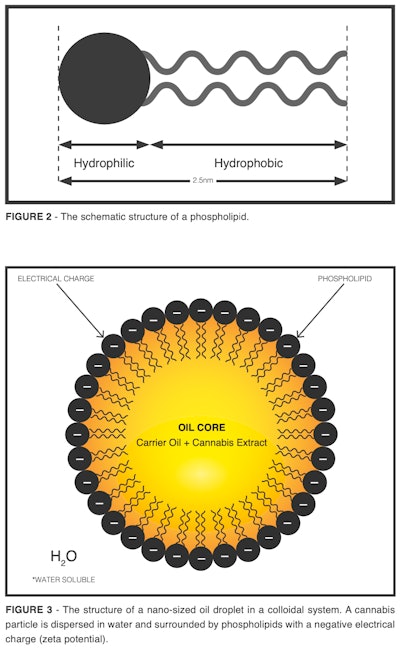

Le Herbe has evolved from just making cannabis nanoemulsions to crafting cannabis powder in 2018. We make healthier formulations for the consumer in a powder form because we encapsulate the nano-sized oil droplets and remove the water. It has less weight, less ingredients, and has a shelf life of 3 years. Add water to our cannabis powder and it transforms back into a stable nanoemulsion. The best quality cannabis nanoemulsions use all-natural ingredients and have fast acting, long lasting, or custom effects.

Our oil-in-water (o/w) nanoemulsions have a mean particle diameter below < 40nm, polydispersity index below < 0.3, and zeta potential below < -30mV. Particle size is calculated using the Stokes-Einstein relation and is implemented in dynamic light scattering (DLS). This powerful instrument collects quality data about particle size distribution, mean particle diameter, and polydispersity index (PDI). A small PDI below < 0.3 indicates good quality, a narrow oil droplet size distribution, and thus better stability. PDI values close to 1 are of poor quality.

The optical appearance of cannabis nanoemulsions are measured in nanometers (nm) and may range from:

1. Transparent systems with particle sizes below < 40nm (clear)

2. Translucent systems with particle sizes between 40-100nm (hazy)

3. Opaque systems with particle sizes above > 100nm (milky white)

Most food industries have grading systems based on particle size and appearance. For example, the coffee industry optimizes for quality by grinding beans to a specific particle size. They measure in micrometers (µm) or sometimes called microns. You have a wide variety of drinks with specific grinds like coarse (1000-2000µm / french press), medium (450- 1000µm / filter drip), espresso (175-450µm), fine (125-175µm), and ultra-fine (50-125µm / Turkish). Small changes in the grind (particle size) can drastically affect the taste of coffee and the amount of caffeine you absorb (bioavailability). Too coarse a grind (large particles) can lead to under-extraction, lack of flavor, and less caffeine. Too fine a grind (small particles) can lead to over-extraction, very bitter flavor, and too much caffeine (dose). Add in water, temperature and pressure to the mix and coffee is complex, but a legal drug enjoyed by everyone in the world. A great cup of coffee needs to be balanced and so does cannabis.

Oral consumption of cannabis needs to be balanced and you should not strive for the smallest particle size. The example above needs to be translated to the cannabis industry because bioaccessability of cannabis nanoemulsions are strongly associated with particle size. Le Herbe recommends that “fast acting” cannabis products have labels that identify particle size with verifiable analysis. We also recommend additional labeling that differentiates all-natural nanoemulsions like Le Herbe from unhealthy formulations like self-emulsifying drug delivery systems (SEDDS). Most countries have laws that protect artisan food and beverage makers so quality doesn’t get corrupted. Le Herbe is not waiting around and is currently developing a grading system for cannabis nanoemulsions and microparticles. Join in on the conversation and lets craft better cannabis products together.

Le Herbe

Le Herbe

Rotor-Stator Mixer

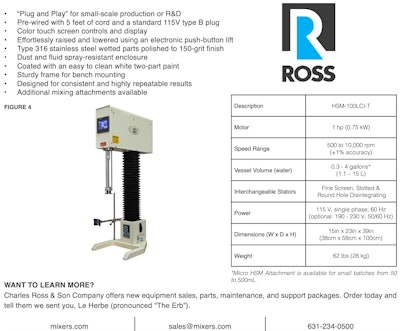

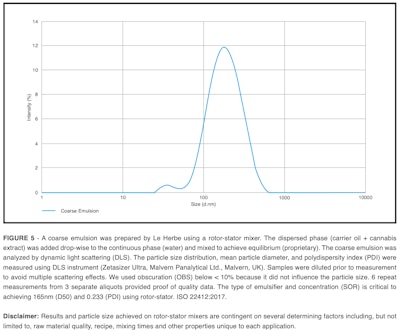

Ross is best in class for making coarse emulsions using a rotor-stator mixer. This is required before you make a cannabis nanoemulsion via high-shear processing. The HSM-100LCI-T can generate oil droplets with precise shape, size, and composition (Figure 4). It’s very important to use the same mixing vessel (size & brand), depth of rotor (based on vessel geometry), and type(s) of stator (screens). The process of when to add ingredients, how to add ingredients, and how long to mix is extremely important! You need to analyze your coarse emulsion using dynamic light scattering (DLS) until you develop SOPs because this will affect the quality of your cannabis nanoemulsion. The HSM-100LCI-T can be purchased with a data-logger program. This enables you to record the speed (rpm), power (amp), and time (sec / min) on a per batch basis. You can track each batch to fine tune or duplicate for product consistency. Le Herbe recommends that you analyze your particle size distribution, mean particle diameter, polydispersity index, and zeta potential of your coarse emulsion before you make a cannabis nanoemulsion via high-shear. We can achieve a particle size of 150-300nm (< 0.3 PDI) with a rotor-stator mixer and a proprietary process (Figure 5). Let us know if you need help with making emulsions or contact Ross to purchase the equipment in the great state of New York (USA).

High-Shear Processing

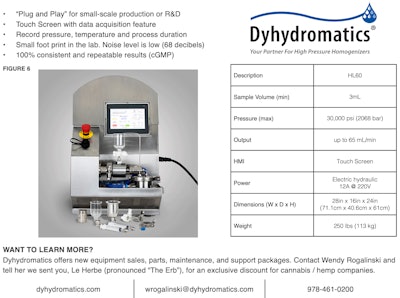

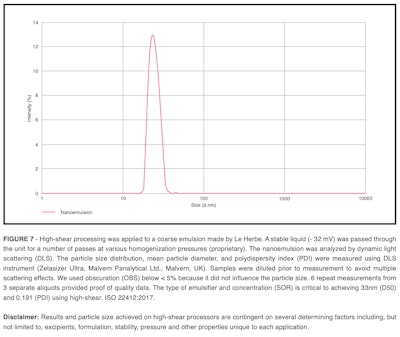

Dyhydromatics is best in class for making nanoemulsions using high-shear processing. This is required before you make cannabis powder via spray drying. The ShearJet® HL60 processor can generate nano-sized oil droplets with precise shape, size, and composition (Figure 6). Initially, the coarse emulsion is made using a rotor-stator mixer which is then fed into the HL60 inlet reservoir. A pumping device helps move the liquid emulsion at constant pressure through a Reaction Chamber®. Within the chamber are micro-channels through which the liquid stream will accelerate to high velocities. The unique fixed-geometry channels are made to collide into each other within the reaction chamber. This creates high-shear rates and impact forces to bring about the desired particle size. Upon exiting the reaction chamber, the product flows through an external cooling coil which regulates the product to a desired temperature. At this point the cannabis nanoemulsion may be recirculated through the system for further particle reduction. Le Herbe recommends that you analyze your particle size distribution, mean particle diameter, polydispersity index, and zeta potential of your nanoemulsion before you make cannabis powder via spray drying. We can achieve a particle size of 25-150nm (< 0.3 PDI) with high-shear and a proprietary process (Figure 7). Let us know if you need assistance with making nanoemulsions or contact Dyhydromatics to purchase the equipment in the great state of Massachusetts (USA).

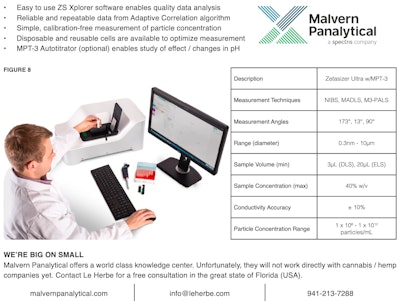

Dynamic Light Scattering +

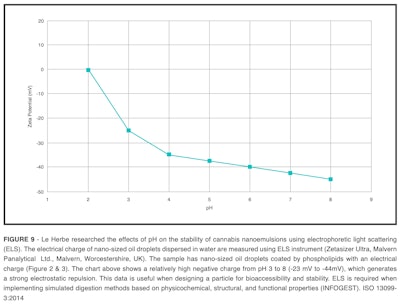

Malvern technology is best in class for implementing dynamic light scattering (DLS) and electrophoretic light scattering (ELS) measurements on your cannabis emulsions. This is required for your coarse emulsion and nanoemulsion before you make cannabis powder via spray drying. The intensity of light scattered by your emulsion depends upon the size, refractive index of the particles, and the angle at which scattering is detected (Mie Theory). This means that particles of different sizes in the same sample are not all detected with the same sensitivity. A traditional single-angle DLS measurement may therefore report a different particle size distribution depending on the angle at which the measurement is performed. In a MADLS® measurement, the correlation data from several detection angles (Back 173°, Front 13°, Side 90°) are combined with this knowledge of Mie theory to generate a higher resolution particle size distribution (Figure 8).

The Zetasizer is used to help design the functionality of bioactive compounds like cannabinoids. It helps optimize cannabis emulsion stability in order to extend product shelf life and improve product performance (Figure 9). It is also used to improve the taste of fresh roasted coffee, artisan chocolate, and much more.

Microparticle

A nanoemulsion is the most versatile delivery system the world has ever seen, but we can make it better. There are some concerns over shelf-stability of nanoemulsions in liquid form due to high susceptibility to microbial spoilage at room temperature. Moreover, it is not feasible to use liquid nanoemulsions in dried food systems. Liquid forms are also difficult to handle during processing, storage, and transportation. Don’t forget to add the cost factors and carbon footprint. Conversion of liquid nanoemulsions into dry cannabis powder can overcome all of these concerns.

Spray drying removes water or solvents from a cannabis nanoemulsion and the nano-sized oil droplets are embedded into a solid matrix called a microparticle. The spray dry process has been used for centuries to encapsulate food ingredients such as flavors, colors, and lipids like powdered milk. We don’t recommend consuming dairy milk, but we see a great opportunity to make plant / nut based milk powders that can be a great alternative or addition to our cannabis powders.

The main factors that affect encapsulation efficiency of cannabis microparticles:

• Properties of oil core (carrier oil, cannabis extract, concentration, volatility)

• Type of emulsion equipment and conditions (coarse emulsion, nanoemulsion, SOPs)

• Characteristics of the nanoemulsion (particle size distribution, mean particle diameter, PDI, zeta) • Type of wall materials (composition, single layer, double layer, particle shell)

• Characteristics of the slurry (total solids, viscosity, water, solvents)

• Type of spray dry equipment and conditions (lab scale, evaporation rate, yield, SOPs)

Your wall material must be carefully selected to ensure the desired properties are achieved in the finished cannabis powder. The thickness of the cuticle and cell wall of resin heads located on stalked glandular trichomes of Cannabis sativa L has been reported to be 500nm [3]. We have moved our knowledge of the properties of cannabis trichomes into the molecular age [4]. When you make cannabis microparticles, you are reverse engineering the structure with all-natural ingredients that are commercially available. You can bring back to life your favorite cannabis strain based on a certificate of analysis (CoA), but you will need isolated cannabinoids and terpenes with high purity to accomplish this feat. If you do not have access to these cannabis extracts then you’re more than welcome to use any extract you want including rosin or distillate. It will be up to the designer to choose how you want to engineer the cannabis powder, what extract / carrier oil to use, and for what purpose (i.e., food, beverage, inhalation).

Le Herbe supports biodynamic farming and uses cannabis extracts from traditional methods like rosin press, SC-C02 and cold ethanol extraction, but a hurricane is coming. Biosynthesis can make isolated cannabinoids with 99.5% purity via yeast for a fraction of the cost of traditional methods. Yeast-based biosynthesis platforms make it possible to quickly and efficiently produce any major or minor cannabinoid at scale in 1 week. Additional labeling should be required if companies choose this route because of ethical concerns. We need to protect artisan makers that use traditional methods and all natural ingredients like Le Herbe.

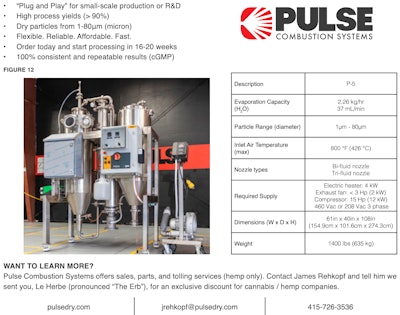

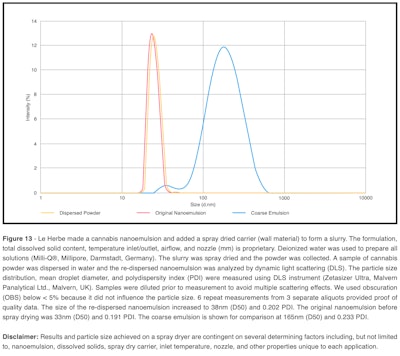

Spray Dying

Pulse-atomization spray drying is best in class for making a dry, shelf-stable, and free-flowing cannabis powder. The dryer is small enough to do development work, but large enough to make reasonable quantities of powder. Spray drying is the most affordable and appropriate method for making high quality powder with specific physicochemical, structural, and functional characteristics. The Pulse Model P-5 Dryer is the most advanced instant drying process to engineer cannabis microparticles in a single step. It is a complete process tool that generates reliable, repeatable, and scalable results. It was designed to be “plug and play” for easy installation, operation, and cleaning. Trolleys allow you to wheel the P-5 spray dryer in and out of the lab to save space when not in use. You can even have a mobile operation if needed in multiple locations. The P-5 delivers significant cost and performance advantages over traditional drying systems (Figure 12). Spray drying demonstrations and training is included with each purchase. Le Herbe recommends that you analyze your nanoemulsion thoroughly with dynamic light scattering (DLS), electrophoretic light scattering (ELS), and simulated digestion (INFOGEST) before and after you make cannabis powder via spray drying (Figure 13). Let us know if you need help with powder formulations or contact Pulse Combustion Systems to purchase the equipment in the great state of Arizona (USA).

Laser Diffraction

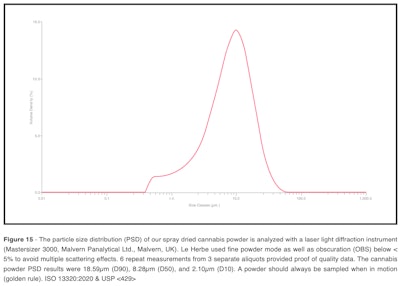

Malvern technology is best in class for implementing laser diffraction on your cannabis powder. This is required for making microparticles based on a quality by design (QbD) principle. The particle size of cannabis powder is an important factor in defining structural, sensory, and functional characteristics. Measurements using the Mastersizer 3000 is used to understand the changes in particle size that occur during production and storage of cannabis powder. This in turn can lead to a better understanding of how product formulation and performance are linked.

A dry system comprises of the main optical unit plus the Aero S dispersion unit (Figure 14). The Aero S is designed for providing an even circulation of dry cannabis powder throughout Mastersizer measurement cell. The microparticles are then pulled through the Mastersizer 3000’s measurement cell using a vacuum. A laser beam passes through the cannabis powder and the angular variation in intensity of the scattered light is measured. Large cannabis particles scatter light at small angles relative to the laser beam and small cannabis particles scatter light at large angles. The spacing and intensity of the rings in the diffraction pattern is related back to the particle size distribution by use of optical models defined by Mie theory (Figure 15), the cannabis industry standard, or Fraunhofer approximation.

Simulated Digestion

In vivo studies are the most accurate methods of determining the impact of specific colloidal delivery systems on the bioavailability of food and beverages infused with cannabis. In these studies, the levels of cannabinoids and their metabolites are measured in the bloodstream, urine, and/or feces over time. Despite their accuracy, animal and human studies are rarely used to test bioavailability of cannabinoids because of their high cost, lengthy timelines, government oversight, potential safety issues, and ethical concerns. Most of the pharmacokinetic (PK) studies are conducted by university and cost approximately $50,000 for animal studies and $150,000 for human studies in USA. You will have to wait 6 months (animal) to 1 1/2 years (human) for the results, but the majority of PK studies do not provide any insights into the physicochemical and structural mechanisms of functional product formulations including but not limited to:

Le Herbe prefers to focus on physicochemical and structural mechanism in vitro and so should you. It is our opinion that the current in vivo approach in USA is not worth the price and frankly a waste of time. Small businesses like Le Herbe have hundreds of formulations. If we tested the traditional route, in vivo, on each one of our formulations then we would be out of business. Plus, formulations change over time so the current study you have a few years ago is not relevant today.

Decades of research have considerably advanced understanding of the critical anatomical, physiological, and formulation factors that control oral bioavailability. This insight enables the whole digestive process to be mathematically modeled. The main outcome of this kind of mathematical model would be the ability to simulate digestion in vitro and thus defer in vivo. The most widely used in vitro digestion method for monitoring the gastrointestinal fate of foods is the standardized INFOGEST method, which is the result of the harmonization of different methods by an international consortium [1]. This method is based on passing a sample through mouth, stomach, and small intestine conditions designed to simulate the human gut (Figure 16). The data is analyzed and the formulation can be adjusted quickly... in as little as 1 day.

Infogest Method

Le Herbe’s cannabis powder is dispersed in water to form a nanoemulsion (Figure 16). The simulated saliva fluid (SSF), simulated gastric fluid (SGF) and simulated intestinal fluid (SIF) for in vitro digestion are prepared with reference to the INFOGEST consensus protocol [5]. A general overview of these methods are given here, but Le Herbe offers consulting services to help with implementation.

MOUTH PHASE

The initial sample is mixed with SSF (1:1 v/v) and incubated for 2 min in a mechanical shaking device to simulate mouth conditions at a speed of 100 rpm (Model 4080, New Brunswick Scientific, New Brunswick, NJ, USA).

STOMACH PHASE

The sample from the mouth phase is then mixed with SGF (1:1 v/v) and incubated under shaking at pH 3.0 for 2 hours to simulate stomach conditions.

INTESTINE PHASE

The sample from the stomach phase is then mixed with SIF (1:1 v/v) and incubated at pH 7.0 for 2 additional hours.

PH-STAT TITRATION

The release of the free fatty acids (FFA) is measured using a pH-stat method and calculated from the amount of NaOH needed for titration (907 Titrando, Metrohm USA Inc., Hillsborough, FL, USA).

CENTRIFUGATION

After digestion, the separation of the lipid phase, micelle phase and sediment phase is achieved by centrifugation of the small intestine sample for 50 min at 18,000 rpm (Sorvall Lynx 4000 centrifuge, Thermo Scientific, Waltham, MA, USA). The bioaccessibility and bioavailability potential of the bioactive compound is determined by measuring the cannabinoid concentration and applying equations (Eq. 1, 2).

Cannabis powder dispersed in water can be assessed at each phase by collecting an aliquot and measuring the concentration, particle size distribution, mean particle diameter, polydispersity index (PDI), and/or zeta potential. This information can provide useful insights into the behavior of cannabis nanoemulsions within the human gut so you can fine tune your cannabis powder for high bioavailability, stability, and ingredient selection.

Summary

Le Herbe is standing on the shoulders of great men and women who stood before us. We offered guidance and provided a standardized method to create cannabis powder or functional ingredients. We recommended specific instruments like a rotor-stator mixer, high-shear processor, and spray dryer. This white paper showed why quality data is key to making nanoemulsions and microparticles with dynamic light scattering and laser diffraction. We briefly explained simulated digestion so you can quickly design cannabis formulations in vitro and defer in vivo. Le Herbe hopes that our efforts help spur the growth of artisan makers all over the world because quality matters.

Our cannabis powder is an evolution of world class R&D and our love for cannabis. Le Herbe published The Art & Science of Cannabis Beverages in 2016 and identified that a nanoemulsion is the gold standard for food and beverage formulations infused with cannabinoids. Even though a cannabis nanoemulsion is the most versatile delivery system the world has ever seen, we can make it better. Le Herbe converted a liquid nanoemulsion with 1 year stability to a cannabis powder with a shelf life of 3 years. These dry microparticles undergo a curing process and get better with age, while cannabis beverages, edibles, and flower degrade over time. Cannabis powder has less weight, less ingredients, and easy to work with compared to liquid formats. We make artisan powder that is fast acting, long lasting, flavorless, odorless, alcohol insoluble, applewood smoked, fizz, foam, and much more.

Le Herbe’s cannabis powder is handcrafted by award-winning chefs and food scientists for a wide variety of uses. We want consumers to drink fresh roasted coffee, espresso, exotic tea, cold pressed juice, and ancient kombucha. We want small businesses to make fresh drinks, artisanal chocolate, fresh baked goods, and delicious pastries. Too many people have given up the right to cook and allowed big corporations to cook for them. This has resulted in a corrupt food system in the USA, which has designed food to be addicting and unhealthy. Growing and making your own food is a privilege that only humans enjoy and should not be taken for granted.

A philanthropic effort needs to help cannabis research in USA because imagine what we could do with more funding. If we had access to more capital then we could design oral formulation to fight disease, sleep disorders, eating disorders, pain management, and mental health issues. Cannabis researchers in the USA desperately need philanthropy to step up and fund important research on the benefits of consuming cannabis. We also need help to de-stigmatize this beautiful plant because it deserves more respect. We think the world would be a better place if we consumed more cannabis and less alcohol.

Let us know what you think and spark up a conversation?