Replacing hand-applied labels with coding solutions allows cannabis manufacturers to automate production processes and use flexible packaging options.

The cannabis industry is undergoing two key trends: switching from conventional packaging to flexible pouches and automating critical processes. As a result, cannabis processors are moving away from using hand-applied labels to display regulatory, branding and production codes and information on their packaging in favor of automated printing and marking solutions.

Choosing the right technology can be challenging, but many solutions support the cannabis industry's evolving needs. For example, cannabis processors need printers and lasers that seamlessly integrate into their packaging lines while helping to ensure clear and accurate printing every time.

With the increasing global acceptance of cannabis, processors aim to enhance the speed, scale, efficiency, and precision of their operations while meeting rising regulatory demands. Adding automation strategies to product labeling reduces manual labor, which frees up resources for critical operations.

Videojet Thermal Transfer Overprinter (TTO) codes on foil cannabis packaging.Videojet

Videojet Thermal Transfer Overprinter (TTO) codes on foil cannabis packaging.Videojet

While jars, tubes and cartons are commonly used for cannabis products, many processors are increasingly choosing flexible film pouches for their products as they are well-suited for automated production processes and provide lightweight, versatile and durable packaging. With an aesthetic appeal and broad printable areas, they are also ideal for promoting brands and products at the point of purchase.

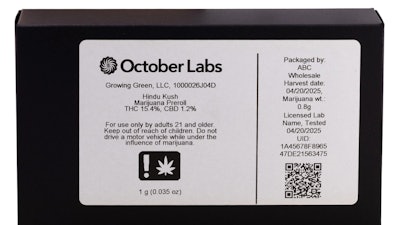

In the U.S., labeling requirements for cannabis products are strictly regulated, constantly evolving and vary by state. Cannabis processors must fit information such as date codes, serial numbers, weight, CBD/THC potency and other details onto varied packaging surfaces while ensuring that the content complements the design of each type of cannabis packaging. These requirements make selecting the proper in-line printing or marking solution critical.

Here are four unique technologies that work well for cannabis operators:

- Thermal transfer overprinting (TTO): TTO is an ideal coding solution for pouches and other flexible film applications, as it is designed to deliver exceptional print quality on roll stock. TTO's high-quality text and graphics and various colors can complement a packaging's design. TTO equipment is easily integrated with vertical form, fill and seal and other pouch and bag equipment.

- Continuous inkjet (CIJ): CIJ technology prints variable text directly onto virtually any type of cannabis packaging. White and yellow inks are often selected to improve readability as they provide strong contrast on dark surfaces such as glass, plastic, metal, paper and cardboard. Food-grade inks enable printing directly on edibles as well as on food-contact surfaces.

- Thermal inkjet (TIJ): Ink-based TIJ printing technology is a great option for printing high-resolution text, 2D bar codes and graphics on cartons, pouches, plastic containers and metal caps. A cartridge contains the printhead and ink supply, so no costly maintenance is associated with pumps, filters or tubing. In addition, the ink cartridges can be easily changed without any special technical expertise.

- Laser marking: Laser marking systems offer flexibility to cannabis processors with their ability to print on a wide range of substrates, including film, pouches, glass, plastic, metal and paper. Direct marking onto edibles and other cannabis products allows the product to carry brand information.

Videojet food grade ink codes on gummies.Videojet

Videojet food grade ink codes on gummies.Videojet